Intertek Hot Tubs A Deep Dive

Intertek hot tubs are a hot topic, and for good reason. This overview delves into Intertek’s role in ensuring the safety and quality of hot tubs, from testing procedures to certification processes and industry impact. We’ll explore the standards, regulations, and consumer benefits of choosing a hot tub with Intertek certification.

Intertek’s involvement extends beyond simple inspections, encompassing a comprehensive suite of tests and evaluations to verify hot tub components meet stringent safety requirements. Different types of hot tubs, from the smallest spas to large hot tub systems, all undergo a similar rigorous process. This ensures that consumers can enjoy their hot tubs with confidence, knowing they’ve passed rigorous quality checks.

Overview of Intertek Hot Tubs

Source: alicdn.com

Intertek plays a crucial role in the hot tub industry, ensuring that these popular relaxation tools meet safety standards and consumer expectations. They act as a third-party certifier, verifying the quality and compliance of hot tubs before they reach consumers. This independent verification helps build trust and confidence in the products.

Intertek’s involvement extends beyond simple inspection; they actively contribute to a safer and more reliable hot tub market. This is accomplished by rigorous testing and certification procedures, which ultimately protect users from potential hazards.

Intertek’s Role in Hot Tub Certification

Intertek’s role is to verify that hot tubs meet various safety and performance standards. This involves a comprehensive testing process to assess critical components like electrical systems, plumbing, and heating elements. They meticulously evaluate the structural integrity of the tub and its materials, ensuring durability and longevity. This comprehensive approach contributes significantly to public safety.

Types of Hot Tubs Intertek Might Inspect

Intertek’s scope of work covers a wide range of hot tub types. This includes traditional above-ground models, as well as more complex and sophisticated in-ground hot tubs. They also likely handle specialized tubs like those with unique features or those designed for specific therapeutic applications. Different models, whether portable or stationary, require different testing protocols.

Standards and Regulations Intertek Adheres To

Intertek’s hot tub testing follows various industry standards and regulations. These standards cover electrical safety, thermal performance, structural integrity, and chemical compatibility, among others. They ensure that the hot tubs meet established guidelines for consumer safety and product performance. Examples of these standards might include those from ANSI (American National Standards Institute) or UL (Underwriters Laboratories). These organizations publish detailed specifications for hot tub components and overall performance, providing a benchmark for manufacturers.

Benefits of Using Intertek for Hot Tub Certification

Manufacturers who use Intertek for certification gain several advantages. Intertek’s independent verification provides valuable credibility and trust with consumers, helping build a positive brand image. The certification process also assures compliance with safety standards, which can reduce the risk of liability. This can potentially lead to a broader market reach, as customers increasingly trust products with independent certification. Furthermore, it assures insurers and regulatory bodies that the products meet required safety standards.

Role of Intertek in Ensuring Hot Tub Safety

Intertek’s role is paramount in ensuring hot tub safety. Their comprehensive testing procedures help identify and address potential hazards. This includes evaluating electrical wiring for short circuits, assessing the structural integrity of the tub to prevent collapse, and examining the heating system to prevent overheating. Intertek’s efforts contribute significantly to the overall safety and reliability of hot tubs. This helps prevent accidents and injuries that might otherwise occur during use.

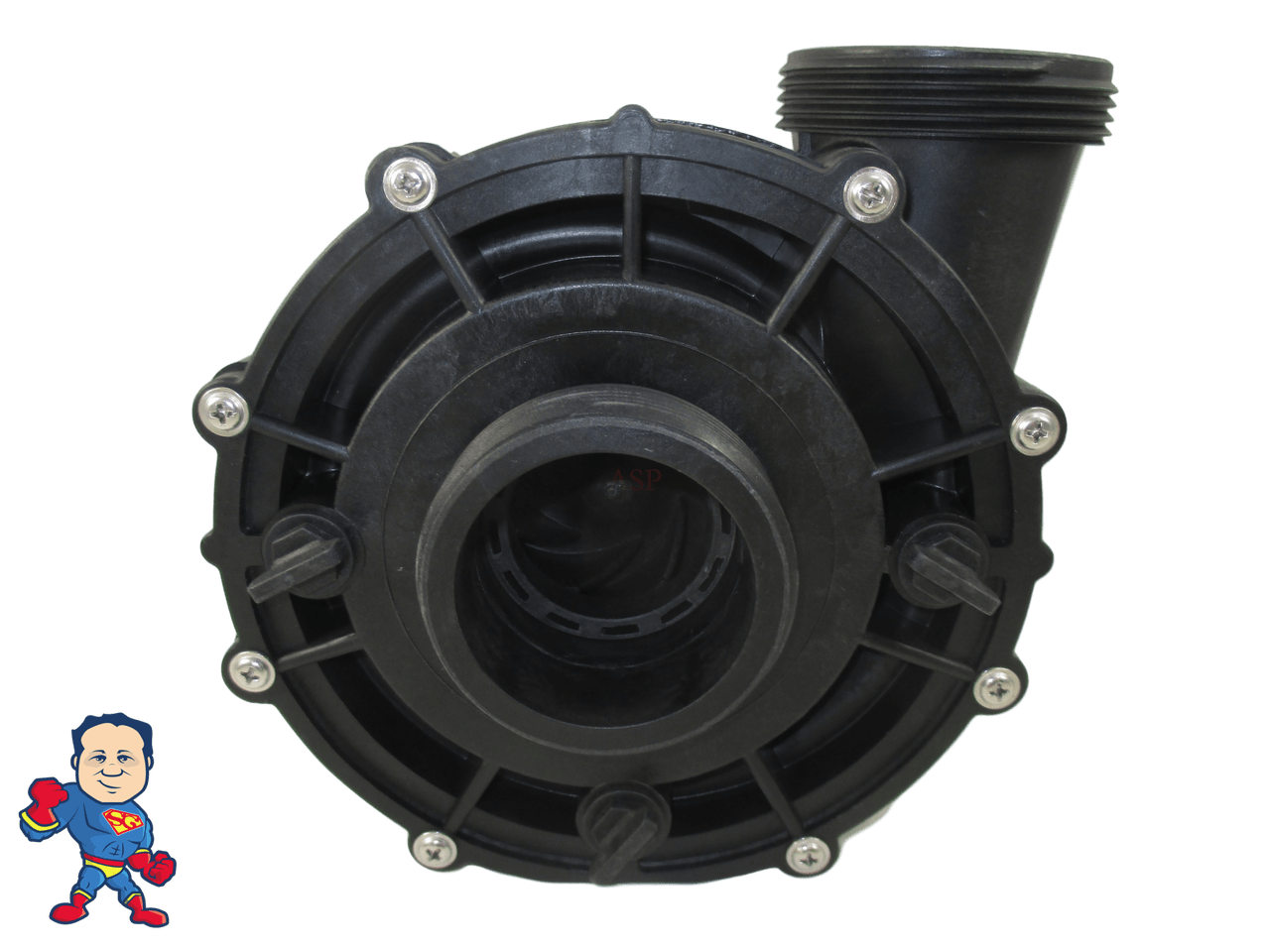

Intertek Hot Tub Testing Procedures

Source: bigcommerce.com

Intertek, a globally recognized testing and certification organization, employs rigorous procedures to ensure the safety and quality of hot tubs. Their testing goes beyond simple visual inspections, encompassing a detailed analysis of various components to guarantee compliance with industry standards and consumer safety. This meticulous approach protects both the manufacturer and the end-user from potential hazards.

Intertek’s testing process isn’t just about checking if a hot tub works; it’s about ensuring it works safely and reliably. This involves evaluating every critical element, from the heating system to the structural integrity of the tub itself. Their detailed approach helps prevent potential issues that could lead to injuries or malfunctions.

Components Tested

Intertek’s hot tub testing covers a wide range of components, ensuring all aspects contribute to a safe and reliable product. This comprehensive evaluation includes the shell, the heating elements, the electrical system, the plumbing, the insulation, and the structural supports. These elements, when properly tested and certified, provide peace of mind for consumers.

Testing Procedure Overview

A comprehensive testing regime is crucial for ensuring hot tubs meet safety standards. Intertek employs a multi-stage approach, starting with visual inspections to identify any obvious defects. This is followed by rigorous functional tests, simulating real-world usage scenarios to uncover potential problems. Finally, destructive tests are performed on select components to evaluate their durability and resistance to common stresses.

Specific Tests

| Component | Test Type | Result |

|---|---|---|

| Shell | Impact Resistance | Passes if the shell maintains structural integrity under specified impact forces. |

| Heating Elements | Electrical Safety | Passes if elements function correctly without causing overheating or electrical shock hazards. |

| Plumbing | Leakage Testing | Passes if no leaks are detected under specified pressure conditions. |

| Electrical System | Short Circuit Detection | Passes if the system is free from short circuits and electrical faults. |

| Insulation | Thermal Resistance | Passes if insulation maintains adequate temperature control within the hot tub. |

| Structural Supports | Load Testing | Passes if supports can withstand expected loads without failure. |

| Water Chemistry | Corrosion Resistance | Passes if materials used for water contact resist corrosion and degradation under operational conditions. |

Importance of Rigorous Testing

Rigorous testing procedures are paramount to ensuring the safety and reliability of hot tubs. Failures in components, even seemingly minor ones, can lead to serious issues like electrical shocks, burns, or structural collapse. The preventative measures taken by Intertek help to avoid these issues and safeguard consumers.

Durability Evaluation Methods

Intertek utilizes a variety of methods to evaluate the durability of hot tub materials. These include accelerated life testing, simulating years of use in a shorter timeframe, to assess the resistance of materials to chemical degradation, thermal stress, and mechanical wear. Furthermore, they employ stress analysis to determine the structural integrity and ability of the hot tub to withstand various loads.

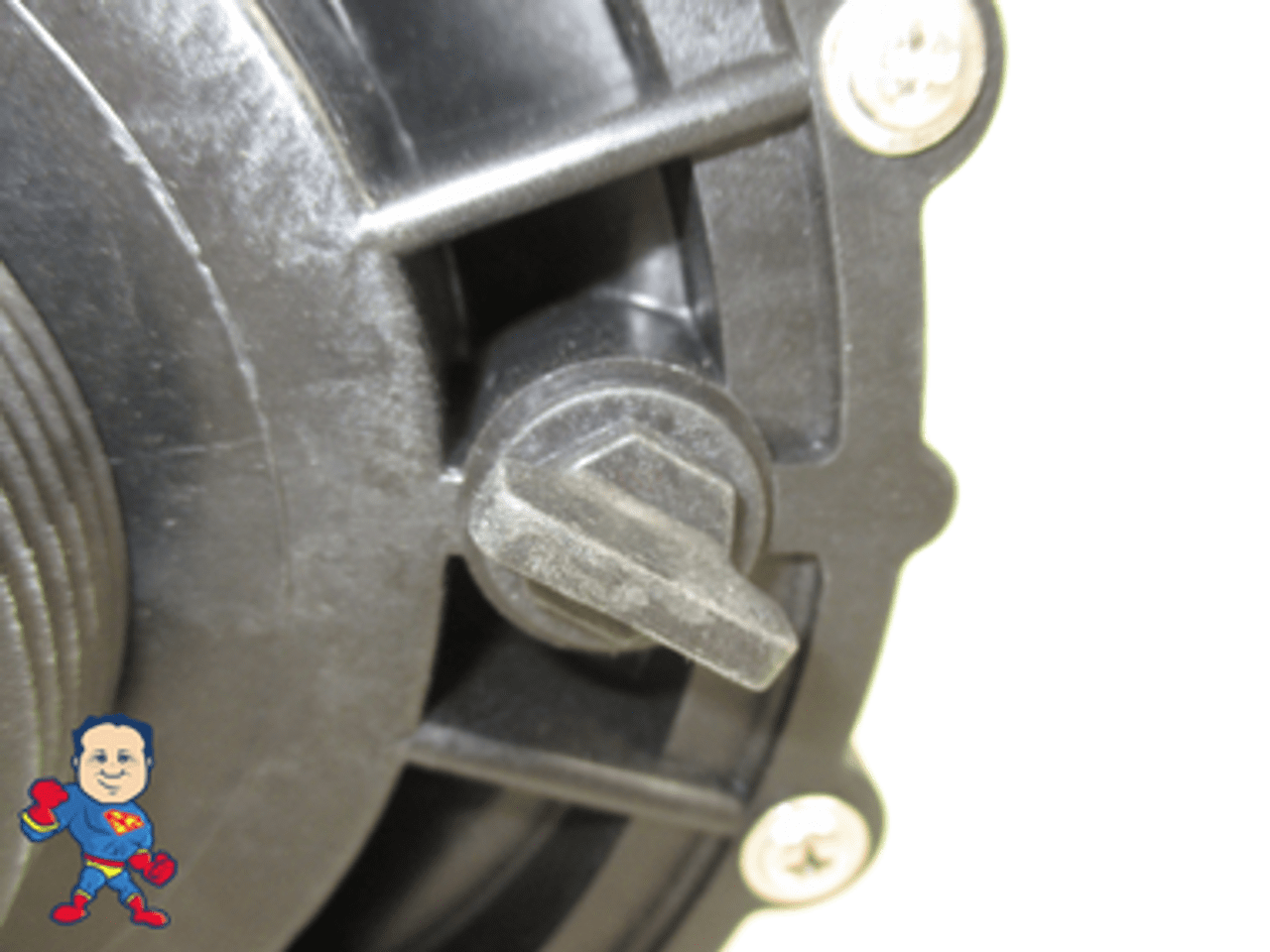

Intertek Hot Tub Certification Process

Source: bigcommerce.com

Getting a hot tub certified by Intertek is a crucial step for manufacturers and retailers. It assures consumers that the hot tub meets safety standards and quality requirements. This process involves a series of steps, ensuring the hot tub is thoroughly evaluated and complies with regulations.

The Intertek certification process is designed to validate the safety and quality of hot tubs. It goes beyond basic compliance, aiming to prevent potential hazards and ensure user satisfaction. This rigorous approach protects consumers and builds trust in the brand.

Certification Stages

The Intertek certification process isn’t a single event; it’s a series of stages that build upon each other. Each stage is carefully scrutinized to guarantee the hot tub meets all the required safety and quality standards. A thorough understanding of these stages is crucial for manufacturers and retailers alike.

- Initial Application and Documentation Review: Manufacturers begin the process by submitting a detailed application package to Intertek. This includes comprehensive documentation outlining the hot tub’s design, materials, and manufacturing processes. Intertek reviews these documents for completeness and adherence to the necessary standards. Any missing information will need to be addressed before the hot tub can proceed to the next stage.

- Factory Inspections: Once the application is deemed complete, Intertek conducts thorough factory inspections. These inspections assess the manufacturing environment, processes, and quality control procedures used to create the hot tub. Inspectors verify that the manufacturing process aligns with the submitted documentation and complies with safety standards.

- Product Testing: Intertek performs rigorous testing on the hot tub to confirm its compliance with various safety standards. These tests may involve evaluating electrical systems, thermal performance, structural integrity, water quality, and more. Different tests are tailored to the specific type of hot tub.

- Compliance Verification: After the testing phase, Intertek meticulously verifies the hot tub’s compliance with relevant safety standards. This stage ensures the hot tub meets the established requirements for its specific type and design. If any issues are identified, manufacturers need to address them and resubmit for re-testing.

- Certification Issuance: Upon successful completion of all stages, Intertek issues a certification for the hot tub. This certification document confirms the hot tub meets the required standards and specifications. The certification acts as a seal of approval, guaranteeing quality and safety.

Types of Hot Tubs and Certification

Different types of hot tubs might have variations in the certification process, depending on their features and complexities. The certification process will adapt to the specific requirements of each hot tub type.

- Standard Hot Tubs: Standard hot tubs typically undergo testing focusing on electrical safety, water pressure, and structural integrity. These tests ensure the hot tub is safe for its intended use and complies with standard requirements.

- High-End Hot Tubs: High-end hot tubs, often featuring advanced technologies and custom designs, may require additional testing and scrutiny. For example, if the hot tub integrates sophisticated electronic components, Intertek will verify those components’ safety and compliance with standards.

- Spa Pools: Spa pools, with their emphasis on therapeutic features, might have additional requirements concerning water chemistry, filtration, and temperature control. These extra considerations will be factored into the testing and certification process.

Key Documents for Certification

Intertek needs specific documentation to thoroughly evaluate and certify a hot tub. The clarity and accuracy of this documentation are crucial for a smooth and efficient certification process.

- Product Specifications: Detailed specifications for the hot tub, including materials, dimensions, electrical components, and mechanical parts. This document provides a comprehensive overview of the hot tub’s design and construction.

- Manufacturing Procedures: Documentation of the manufacturing processes used to create the hot tub. This includes quality control measures, assembly instructions, and materials used. This documentation ensures consistency and reliability.

- Test Reports: All test results obtained during the certification process are documented in detailed test reports. These reports are crucial for confirming compliance with safety standards.

- Safety Data Sheets (SDS): SDS for all materials used in the hot tub are essential for health and safety purposes. This information ensures proper handling and disposal procedures.

Intertek’s Role in Compliance

Intertek acts as a neutral third-party certifier, ensuring hot tubs comply with safety standards. Their role is critical in upholding consumer safety and protecting manufacturers from liability.

- Ensuring Safety: Intertek’s rigorous testing and inspections guarantee that hot tubs meet safety standards, protecting consumers from potential hazards. This role is crucial in the industry.

- Promoting Trust: Intertek certification builds trust in the hot tub brand, showcasing that the product meets high quality and safety standards. This is important for consumer confidence and brand reputation.

- Facilitating Compliance: Intertek assists manufacturers in achieving compliance with the relevant safety regulations, minimizing potential issues or violations.

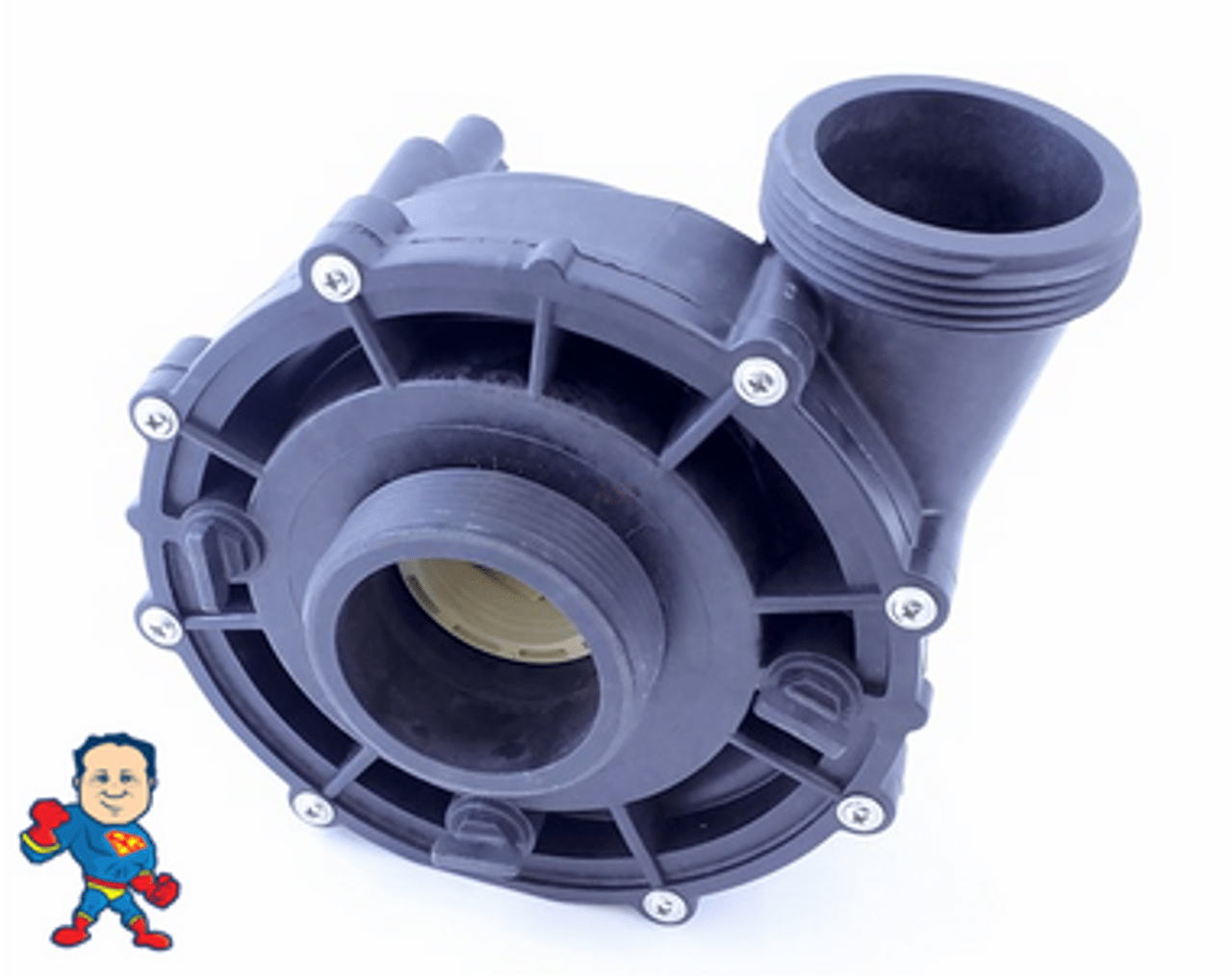

Intertek Hot Tub Quality Standards

Source: bigcommerce.com

Intertek’s hot tub quality standards aren’t just some arbitrary rules; they’re the bedrock of a safe and enjoyable hot tub experience. These standards are rigorously enforced to ensure that hot tubs meet specific safety and performance criteria, protecting both consumers and the industry as a whole. Understanding these standards is crucial for anyone looking to purchase or sell a hot tub.

Intertek’s Evaluation Criteria

Intertek employs a multifaceted approach to evaluating hot tubs, encompassing various aspects of design, construction, and performance. Their comprehensive assessment covers everything from the materials used in the tub’s construction to the efficiency of its heating and circulation systems. This rigorous evaluation ensures the safety and functionality of each hot tub.

Key Quality Parameters

Intertek meticulously scrutinizes numerous parameters to guarantee quality. These parameters are critical for maintaining a high standard within the hot tub industry.

| Parameter | Description | Measurement |

|---|---|---|

| Electrical Safety | Ensuring the hot tub’s electrical components are properly insulated and grounded, preventing electric shocks. | Compliance with relevant electrical codes and standards (e.g., UL, CSA). Visual inspection, insulation resistance tests, and ground fault circuit interrupter (GFCI) testing. |

| Structural Integrity | Assessing the strength and durability of the hot tub’s shell and components to withstand expected use and stresses. | Load tests, material strength analysis, pressure testing. |

| Water Quality & Treatment | Evaluating the efficiency of the water treatment system, ensuring the maintenance of clean and safe water conditions. | Water chemistry analysis (pH, alkalinity, sanitizer levels), filtration system performance testing. |

| Heating & Circulation | Assessing the efficiency and reliability of the hot tub’s heating and circulation system. | Heat output measurements, pump performance testing, temperature control accuracy. |

| Plumbing & Components | Evaluating the integrity of the plumbing system and all components to prevent leaks and ensure proper function. | Leak detection tests, pressure testing, component function verification. |

| Safety Features | Evaluating the presence and proper functioning of safety features such as covers, drains, and emergency shutoffs. | Functional testing of each safety feature, visual inspection, and documentation. |

Impact on the Hot Tub Industry

Intertek’s standards have a profound impact on the hot tub industry. By setting high standards, Intertek promotes a culture of quality and safety, fostering consumer trust and confidence. This, in turn, elevates the overall reputation of the industry.

Consequences of Non-Compliance

Failure to meet Intertek’s quality standards can result in significant consequences for hot tub manufacturers. This may include product rejection, delays in market entry, and damage to the company’s reputation. In some cases, corrective action may be necessary to rectify issues and regain certification. The repercussions can be substantial.

Customer Confidence

Intertek’s rigorous standards contribute significantly to customer confidence. Consumers can trust that hot tubs certified by Intertek meet specific safety and performance criteria. This fosters trust and allows consumers to confidently purchase hot tubs. Examples include verified energy efficiency, safety, and reliable performance, which builds consumer trust and confidence in the brand.

Intertek Hot Tubs

Source: bigcommerce.com

Choosing a hot tub is a big decision, and ensuring its safety and quality is paramount. Intertek, a globally recognized testing and certification organization, plays a crucial role in verifying the safety and reliability of hot tubs. This section focuses on the value Intertek certification brings to consumers.

Consumer Value of Intertek Certification

Intertek certification acts as a powerful assurance for consumers. It signifies that the hot tub has met rigorous safety standards, ensuring a product designed for responsible use and lasting enjoyment. This independent verification builds consumer confidence, knowing that the hot tub has undergone comprehensive testing to meet specific requirements.

Impact of Intertek on Consumer Trust

Intertek’s rigorous testing procedures, documented in detailed reports, directly influence consumer trust. This independent verification process assures consumers that the hot tub meets specific safety and performance criteria, reducing concerns about potential hazards. Consumers can feel more confident in the hot tub’s durability and longevity.

Hot Tub Safety for Consumers

Hot tub safety is critical for a pleasurable and risk-free experience. Consumers should prioritize features like properly functioning electrical systems, robust structural integrity, and effective safety mechanisms. Understanding these elements is key to a safe hot tub experience.

Comparison of Hot Tub Brands and Intertek Certifications

| Brand | Certification Status | Key Features |

|---|---|---|

| AquaSource | Intertek Certified | Durable construction, advanced filtration system, multiple safety features, and reliable heating elements. |

| Relaxation Spas | Intertek Certified | Sleek design, innovative jets for massage therapy, automatic safety systems, and reliable insulation. |

| HydroLuxe | Intertek Certified | Advanced control panel, powerful jets, durable materials, and safety features including automatic shutoff systems. |

| Premium Pools | Not Intertek Certified | Basic design, and some safety features, but lacks advanced safety systems. |

The table provides a snapshot of hot tub brands and their Intertek certification status. This information is vital for consumers making purchasing decisions, allowing for informed comparisons based on quality and safety.

Benefits of Purchasing a Certified Hot Tub

Purchasing a hot tub with Intertek certification offers several tangible benefits. It demonstrates the manufacturer’s commitment to safety, enhances the product’s perceived value, and assures the consumer of meeting specific safety standards. This, in turn, can increase the resale value of the hot tub and provide greater peace of mind.

Intertek Hot Tubs

Source: bigcommerce.com

Intertek’s involvement in the hot tub industry goes beyond simple testing. Their standards and certification processes significantly impact the entire manufacturing chain, from design to final product. This influence extends to consumer safety, economic factors, and the industry’s overall reputation.

Intertek’s rigorous testing and certification procedures contribute to a more reliable and trustworthy hot tub market. This translates to enhanced consumer confidence and a competitive advantage for manufacturers who meet Intertek’s high standards.

Impact on Hot Tub Manufacturing, Intertek hot tub

Intertek’s standards influence hot tub manufacturing in several crucial ways. These standards drive manufacturers to implement safer designs, more durable materials, and better quality control procedures. This proactive approach ensures that hot tubs are not just functional but also long-lasting and safe for consumers.

Economic Implications

Intertek’s presence in the hot tub market has clear economic implications. Manufacturers who adhere to Intertek standards are more likely to gain consumer trust, which can lead to increased sales and market share. Conversely, manufacturers who disregard these standards risk reputational damage and potential legal issues. The overall market benefits from greater consumer confidence and reduced risks associated with product failure.

Quality Improvement Examples

Intertek’s standards lead to tangible improvements in hot tub quality. For example, their testing procedures ensure that hot tubs meet specific electrical safety standards, preventing potential shocks. Furthermore, Intertek’s material testing helps guarantee that the materials used in hot tubs are durable and resistant to common wear and tear. These rigorous checks translate to longer-lasting hot tubs, providing greater value to consumers.

Promoting Industry-Wide Safety Standards

Intertek plays a crucial role in establishing and enforcing industry-wide safety standards for hot tubs. By setting these standards, Intertek creates a level playing field for all manufacturers. This fosters a more responsible and safer hot tub industry, benefiting both consumers and manufacturers.

Public Health and Safety

Intertek’s rigorous testing and certification processes directly contribute to public health and safety. By ensuring that hot tubs meet established safety standards, Intertek minimizes the risk of accidents and injuries. This proactive approach reduces potential liabilities for manufacturers and promotes a safer environment for consumers.

Intertek Hot Tubs

Source: bigcommerce.com

Intertek plays a crucial role in ensuring the safety and quality of hot tubs worldwide. Their rigorous testing and certification processes are essential for consumer confidence and industry standards. This section explores the anticipated future trends in hot tub testing and certification, along with Intertek’s role in adapting to these changes.

Future Directions of Hot Tub Testing and Certification

Intertek will likely continue to evolve its testing methodologies to address emerging materials and technologies in hot tub construction. This includes advancements in insulation, heating systems, and energy efficiency, all demanding new testing protocols to maintain safety standards. Expect an increased focus on sustainability and eco-friendly materials, which will necessitate new certification criteria for environmental impact. Furthermore, the increasing use of smart technologies within hot tubs will require specialized testing for electrical safety and data security.

Potential Advancements in Hot Tub Safety Technology

Safety is paramount in the hot tub industry. Expect advancements in sensors and monitoring systems to enhance safety. Real-time monitoring of water chemistry, temperature, and occupancy levels will be crucial. Predictive maintenance systems will likely become more prevalent, alerting users to potential problems before they escalate. Integration of these systems with smart home platforms could provide a comprehensive safety network, enabling remote monitoring and proactive intervention. Examples include automatic shutoff features in response to unusual temperature changes or water quality readings.

Intertek’s Role in Adapting to Future Industry Needs

Intertek’s ability to adapt to future industry needs is essential for maintaining its position as a leader in hot tub certification. This includes investing in research and development to stay ahead of emerging technologies and safety concerns. Developing partnerships with industry experts and academic institutions is another key aspect of this adaptation. Furthermore, Intertek will likely need to expand its training programs for inspectors and assessors to keep pace with these advancements.

Evolving Hot Tub Standards and Regulations

Hot tub standards and regulations are continuously evolving to reflect the latest safety research and consumer expectations. This includes adapting to new materials, construction techniques, and safety features. Regulations regarding energy efficiency, water conservation, and environmental impact will likely become more stringent. Furthermore, international harmonization of standards is likely to increase, fostering a global approach to hot tub safety. Expect more detailed standards for smart technology integration to address potential risks.

Potential Challenges for Hot Tub Manufacturers in the Future

“Staying ahead of evolving safety standards and testing protocols will be a significant challenge for hot tub manufacturers in the future. The costs associated with adapting to new technologies and certifications could potentially increase production expenses. Maintaining high-quality standards while balancing affordability will also be a significant hurdle.”

Epilogue

Source: bigcommerce.com

In conclusion, Intertek hot tubs represent a commitment to safety and quality that benefits both consumers and the industry. By adhering to rigorous standards, Intertek ensures that hot tubs are built to last and meet safety standards. This, in turn, builds consumer trust and reinforces the importance of quality in the hot tub market. The future of hot tub safety looks bright, with Intertek likely at the forefront of innovation and adaptation.